What is a

Sheet Metal part of a car? Generally refers to the car's metal shell, which is usually made of steel, on the basis of ensuring a certain degree of strength, as far as possible to reduce weight is its basic requirements. In addition to the protection and aesthetic functions, automobile sheet metal parts are the main carrier for the car to withstand the gas resistance. Therefore, the quality and longevity of automotive sheet metal parts not only affect the aesthetic appearance of the car, but also increase the resistance of the air to the car due to the quality and deformation, and cause the economy to decline.

1, sheet metal parts and their classification

Automobile sheet metal parts can be divided into two categories according to the manufacturer: original parts and deputy parts. The so-called "original factory" generally refers to the loading of parts for the vehicle manufacturer; "sub-factory" is the non-matching parts produced by non-supporting manufacturers. The price of most of the original parts is higher than that of the vice parts. Most people think that the original parts that were replaced at a special service station or the original parts purchased in the auto parts market should be the same as the original car. In fact, there may be big or small differences among them. For example, the "original" type sheet metal parts are further divided into several grades: the first grade is the best quality, and is a special loading part, that is, the original car belt, which cannot be purchased outside; the second grade product The supply of special service stations, in addition to installation or replacement process may bring about the gap, the product itself and the first level is not much difference; the third level is the flow of accessories to the retail market, although the sale is still It is a relatively high price for the original part, but in fact its quality cannot be compared with that of the original original car. The product quality of [deputy factory" parts is also mixed. The products of the [sub-factory" automotive sheet metal parts of Grade 1 are almost comparable to those of the original parts. This type of products are mainly from companies with strong capital and hardware, and they have to select materials. Pipeline machinery operations can ensure standardization; secondary "by-plant" parts, used materials and manufacturing processes are inferior to the first-class products; and the last category is the most indispensable, no quality at all, only low The price is to blind consumers. Some repair stations operate in violation of the regulations. The so-called original parts are in fact poor quality [deputy factory parts" that are wholesaled from the auto parts market. In order to win huge profits, they will be sold under the [original" banner when selling to owners, and their prices will naturally be Far more than the auto parts market. So, how to distinguish the merits of sheet metal parts? To this end, we have consulted senior technicians who have years of experience in car sheet metal repairs.

2, how to distinguish the merits of sheet metal parts

According to Master Jinuo Luo, the quality of the sheet metal parts must be discerned. In general, the packaging, weight, welding process, painting process, and the degree of matching at the time of loading can be used. It is very difficult for ordinary car owners to tell whether or not the sheet metal parts are of high quality after delivery. It may be possible to distinguish from the packaging of the products in advance: Generally, the products produced by the small factories will not be printed on the contact information and site, but the regular manufacturers. In addition to the contact information and the site, there will be seals, qualifications, and inspection labels on the product. Even if consumers have problems in the future, they may have rights protection.

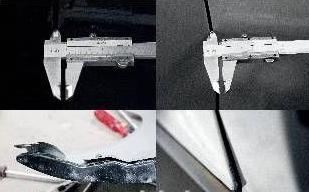

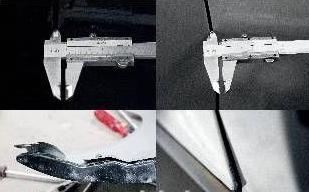

Product weight is one of the test standards for measuring the quality of sheet metal parts. In order to ensure the safety of automobiles, the steel plates used in automotive sheet metal parts must reach a certain weight. The weight of the original sheet metal parts and the quality of the deputy factory sheet metal parts should be almost the same, and if you buy a sheet metal piece that is one-third lighter than the original sheet metal part, then you will undoubtedly buy it. It will be a small factory's product. As for the welding process, it is also a method of discriminating whether or not sheet metal parts are from large companies. The sheet metal parts produced by the regular manufacturers will use the mechanical cutting and welding operations, and the solder joints or trimming edges are smooth and smooth, and will not leave rough cutting edges.

Many car owners think that the sheet metal part still needs to be sprayed with the same color of car paint as the original car. Therefore, when the sheet metal part is purchased, the painting process of the sheet metal part is ignored and it is irrelevant, but this idea is incorrect. . In order to prevent oxidation and rust, the sheet metal parts need to be spray-painted prior to leaving the factory. Indeed, after the sheet metal parts are replaced, the painting part can be used to protect and prevent oxidation, in addition to its tinting. If it is a sheet metal part of a small factory, if there is uneven absorption and foaming during the painting process at the time of production, the effect of the final painting will be affected, causing it to easily fall off, cause corrosion, and affect and damage during the process of use. Sheet metal quality.

The degree of coincidence of sheet metal loading is also a key point in distinguishing the quality of sheet metal parts. It will determine whether the final result of loading is beautiful, and at the same time determines the degree of difficulty in installation. Therefore, many sheet metal maintenance engineers are also very concerned about. the elements of. If the fitment of the sheet metal parts to the original car is low, such as the hole position cannot be aligned, the error in the loading clearance and flatness is excessive (the one-way tolerance of high-quality sheet metal parts in this respect is to be controlled below 1.0 mm). Basically it can be determined that this is a substandard product from a small factory. Master Luo said that few car owners noticed that a strong collision would cause slight deformation of the entire vehicle body. At this time, if the hard metal parts with larger gaps are installed, the car body will be deformed again, affecting the damaged vehicles. Restore the original appearance and quality. Although experienced sheet metal mechanics will eventually adjust the sheet metal part to a better loading effect through drilling and welding, this can be time consuming and laborious. In addition, the quality and life expectancy are not as good as those produced by machinery. Sheet metal pieces are good. Therefore, when the car owners choose to buy, they should choose the original parts or the first-level auxiliary parts that match the original car clearance degree, and they can be installed in one step, avoiding or reducing the [secondary processing" of the sheet metal master. hurt.

The above is some knowledge to distinguish the quality of automotive sheet metal parts, hoping to give some friends who need to buy sheet metal parts of some help. Of course, it does not mean that the selection of high-quality sheet metal products can be completely ignored. Like many parts of automobiles, sheet metal parts also need reasonable use and maintenance. Minimizing open-air parking and driving in sand, regularly spraying paint on the inside of sheet metal parts to prevent corrosion is the key to prolonging the service life of sheet metal parts.

Tips:

1. High-quality sheet metal parts need to be produced by machinery. The solder joints and trimming edges are smooth, with no rough edges. 2. High-quality sheet metal parts are very particular about the baking paint technology, requiring uniform components, strong adhesion, and good waterproof and oxidation resistance. There is only 0.3mm difference between the clearance of the first-grade deputy factory piece "Xinyi" and the original car.

4. The hole position of poor quality sheet metal parts will not be aligned and it will be necessary to re-drill the holes 5. The flatness of poor quality sheet metal parts requires larger adjustments.

Ms. Hilda Yu

Ms. Hilda Yu

What is a Sheet Metal part of a car? Generally refers to the car's metal shell, which is usually made of steel, on the basis of ensuring a certain degree of strength, as far as possible to reduce weight is its basic requirements. In addition to the protection and aesthetic functions, automobile sheet metal parts are the main carrier for the car to withstand the gas resistance. Therefore, the quality and longevity of automotive sheet metal parts not only affect the aesthetic appearance of the car, but also increase the resistance of the air to the car due to the quality and deformation, and cause the economy to decline.

What is a Sheet Metal part of a car? Generally refers to the car's metal shell, which is usually made of steel, on the basis of ensuring a certain degree of strength, as far as possible to reduce weight is its basic requirements. In addition to the protection and aesthetic functions, automobile sheet metal parts are the main carrier for the car to withstand the gas resistance. Therefore, the quality and longevity of automotive sheet metal parts not only affect the aesthetic appearance of the car, but also increase the resistance of the air to the car due to the quality and deformation, and cause the economy to decline.