# Cnc Machining

One Stop CNC Machining Service

- 100,000+ Parts Manufactured

- 20+ Years Manufacturing Experience

- 100+ Manufacturing Centers

- ISO 9001:2015 Certified

- 50+ Countries Shipped

Get an Instant Quote Now

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploaded files are secure and confidential

Tight Tolerance

Client To Work With

Machines Set

CNC Parts Monthly

YPMFG Manufacturing Capabilities

Our Professional CNC Services

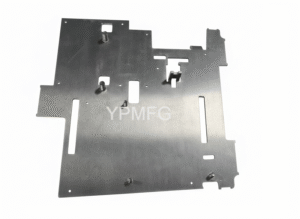

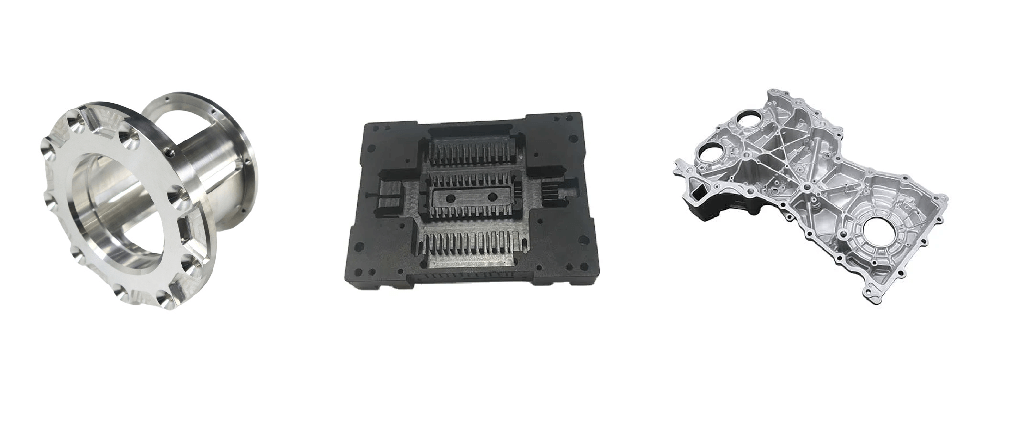

CNC Machined Products We’ve Made

We provide professional CNC machining services for a wide range of industries, delivering high-quality CNC machined parts with exceptional accuracy and finish. From prototyping to production, our CNC machining capabilities meet the demands of complex, custom, and high-performance components.

Our Machines

We deliver high-precision custom parts using top-tier CNC machines, including Nakamura-Tome, Okuma, Mazak, Mikron, DMG Mori, Tsugami, Gleason, and more. Our advanced equipment ensures tight tolerances, fast turnaround, and consistent quality for both metal and plastic components.

Why You Can Trust YP-MFG

Cost-Effective Solutions

Savings of 30–50%, achieved through our efficient production and cost controls, deliver exceptional value you can trust.

Quality Assurance

Certified under ISO 9001:2015, every part is thoroughly inspected to ensure consistent quality, durability, and performance.

Manufacturing Experience

YP-MFG operates over 100 high-precision CNC machines across a 2,000㎡ modern facility, we support both rapid prototyping and mass production, offering scalable solutions for various industries.

Engineering Support

YP-MFG skilled engineering team provides DFM analysis, material consulting, and technical optimization throughout your project. We help reduce cost, improve functionality, and accelerate your time-to-market.

How to Work With Us

Parts Delivered

After your precision-machined parts undergo rigorous quality inspections, they are shipped to you.

Industries We Serve

For over 20 years, YP-MFG has been making high-quality parts on demand for industries worldwide.

Medical Device

CNC machining for medical device components and medical implants, ensuring safety and reliability.

Learn More

New Energy

Precision components for solar panels, turbine components for wind power generation, and more.

Learn More

Robotics

Custom robot components with tight tolerances for smooth movement and high efficiency.

Learn More

Automotive

Fast prototyping and durable parts for engines, chassis, and EVs, all made with precision.

Learn More

Consumer Products

From home appliances and electronics to personal care devices, and more.

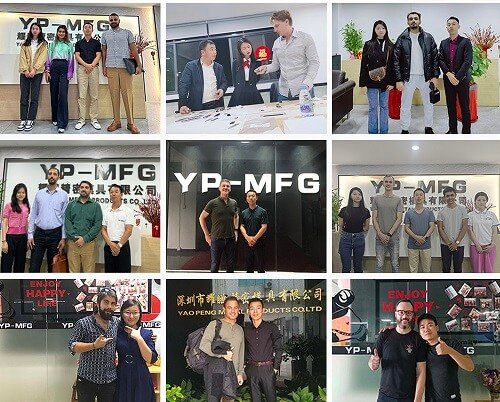

Learn MoreOur Most Satisfied Customers!

See Why 2000+ Clients Trust Our CNC Machining Service

Excellent service and support. Katherine communicated changes and updates, while the engineers helped to make my design manufacturable. The precision components it should staystronger as well after material revision. The results were a beautiful part delivered in a timely manner will work with again for future needs. The customer for robotic parts praised your work very much. The parts are of highquality ! Thank you very much.

YP-MFG successfully handled parts that were extremely difficult to manufacture, includingcomplex molds, and delivered everything on time. Their service and communication werevery satisfactory-smooth and stress-free from start to finish. The sales representative wasdilicent, careful, and truly conscientious. Even the final paintwork, based on only a roughidea from my side, turned out better than expected, True professionals.

We were under extreme pressure with cargo flights booked, zero stock, and full focus onassembly. YP-MFG stepped in at a critical time and delivered without a single issue. Their communication and service were excellent-fast, clear, and stress-free, The salesrepresentative was exceptionally diligent, detail-oriented and makes the whole processstress-free. When reliability matters most, YP-MFG is the partner to trust.

Our Latest News

Company News, Industry Information, and more.

Start Your Production Services Now!

Upload Your Project File → Get Instant Quote → High-Precision Parts in Hand!