The CNC fabrication services happen to be the enchanting and beneficial feature within manufacturing globe. CNC stands for computer numerical control where a machine follows some programs to build parts and components precisely. This guide will provide a deeper understanding of CNC fabrications services, outlining what they are and the benefits that come with them while improving your manufacturing process.

One of the major benefits of CNC fabrication services is how it allows for unprecedentedly accurate part manufacturing. The final result comes astonishingly close to being 'better than human', with the computer managing both cutting and shaping tasks. Especially in industries such as aerospace, and medical device manufacturing where the minutest deviations of parts carry some serious consequences.

The other advantage is that a CNC machine will produce parts very quickly and with great efficiency. Those machines can run 24/7, meaning unattended hours for parts by the hundreds. The minute allows for production rates to even-sheer through in a reasonable amount of time, minim you need massive output runs accomplished. Also, since the machine is controlled by a computer, less resources are wasted on defective parts.

The CNC fabrication services have a great way of optimizing the way you manufacture things. Ongoing operation of these machines mitigates downtime between production runsoverall; High efficiency in production shedules. Moreover, the high quality of parts produced also reduces or eliminates any requirement for post-processing machining / finishing which in turn saves valuable time and costs.

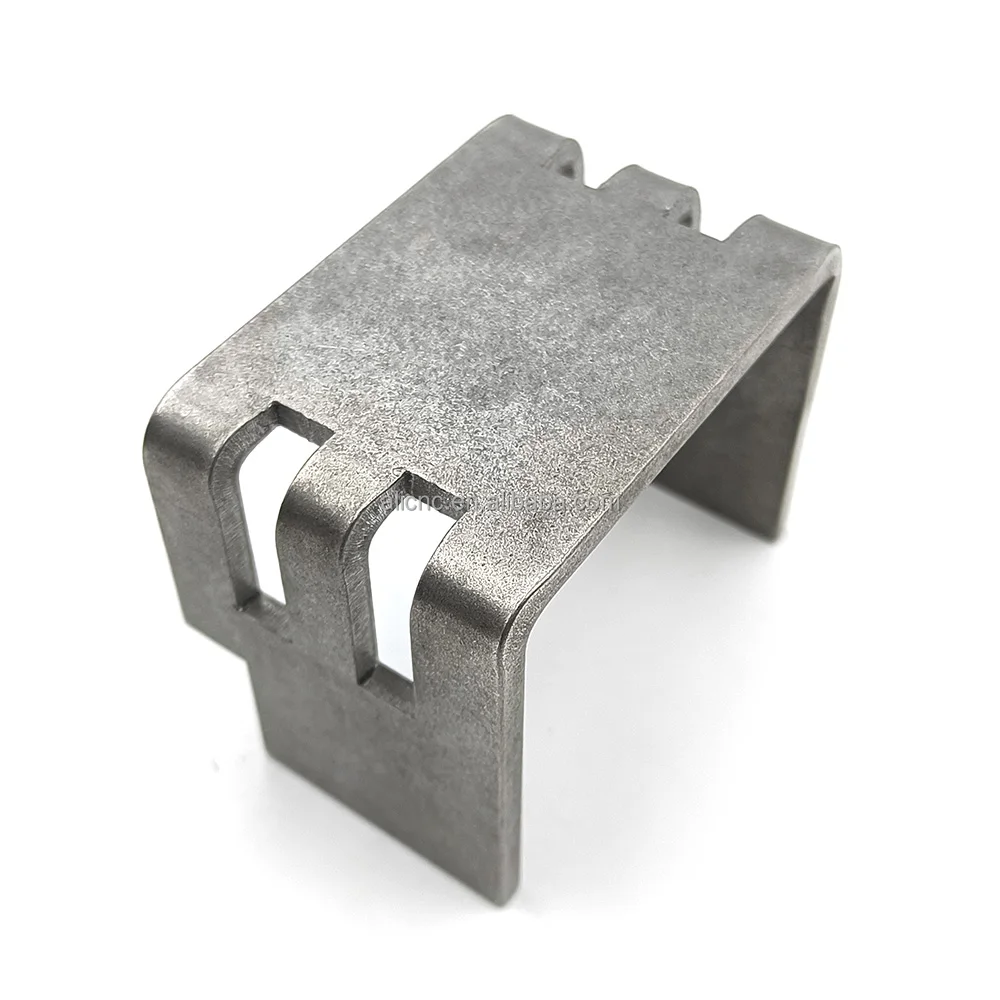

Besides, CNC fabrication services are a solution for designers who desire far more freedom and flexibility in what they create. This precision of these machines in producing parts allows completion of complex shapes and features that would otherwise be difficult or impossible to achieve with traditional manufacturing.

In conclusion, CNC fabrication services are an important part of the manufacturing environment. They enable the manufacture of mechanical parts and items down to precise dimensions, reduce the amount of production time it takes to create a finished product, and make designers broaden their scope by miles. If you are looking for a manufacturing partner, look at companies that provide CNC fabrication services so your parts could be crafted with the highest accuracy and precision while freeing up time to focus on designing innovative products which improves our world.

The YP-MFG adheres strictly to ISO 9001-2015 cnc fabrication service standards.The dimensions are tested both prior to and following surface treatment.We can satisfy special drawings needs and more.

YP MFG home to more than 70 of the latest equipment ensuring quality prompt speed delivery.machines cnc fabrication service Milron from Switzerland, Brother from Japan, Jingdiao from China many more.have 15 sets of 5 axis turning machines, 39 sets of 3 and 4 axis milling machines that axis-oriented, as well as 16 sets turning machines.

YP MFG able to provide an array CNC cnc fabrication service service.include CNC machining, CNC milling, CNC turning, laser cutting, die-casting, forging, all kind surface treatment, assembly so on.

YP MFG has been in cnc fabrication service processing for longer than 20 years. our engineers are highly skilled.Our customer are from allover the world, EU, US, AU, Asian.More than 90% of our products are export to allover the world.Through our 20 years of experience, we have learned about different cultures and requests of different areas and requirements that are utilized in various places.