Example a machine, as yet more capable which almost certainly now can do Things Humans cant. This is incredibly important in creating things that we use cars, plane or buildings. This article will definitely focus on this kind of machine, CNC milling machinery for you to mill some raw materials into an variety of intricate shapes. The machine that we are featuring is a CNC; which, again stands for Computer Numerical Control - the computer controls how it moves. Meaning, This article is about the future of Titanium and how CNC milling will see it at full weight to dominate.

The 5 Top Benefits of CNC Milling Titanium - Revealed

Titanium is also a rare metal with one of the highest strength to weight ratios. This is crucial for airplanes, ships and even medical materials like surgical implants. But one of the drawbacks is that titanium, which unlike elastic materials has no 'shrink', it just stands tall with such strength so if you want a part to be bigger or smaller...good luck doing anything. However, they deliver on this in the other category due to their utilization of CNC milling machines. Because CNC milling is more precise and quicker to cut into the metal, it can be employed for creating intricate cosmetic patterns or geometric shapes on titanium.

CNC millingput more accurately, cutsaway the raw material from a whole part rather than carving to shape which gives them much tighter tolerances and outcomes. The Titanium is a metal with some unique attributes which provide the technology to be one of its kinds. Working with titanium is not easy but its CNC milling allows the fabrication to be carried out more smoothly and give high-quality parts in a lesser period of time Cheap to Produce: The higher the efficiency, the less it costs to make.

Machining titanium was very challenging in the past because of its chemical and physical properties. On the bright side, there are CNC milling machines that can handle this troublesome metal machining. While at the same time fully supporting even the most difficult grades of titanium, fabricating parts with an unmatched level if ulterior precision and quality. By a series of tools, all feeding from titanium to aid in the machining approach we know CNC milling machines (computer programmed robots who perform complex jobs executed with much greater accuracy & proficiency.

StefanO created a write-up onCalibration: Milling High-Performance Titanium ComponentsThe CNC milling process for titanium components is slow, long and very fine - so it ist important to calibrat... When you design an idea that will be used over and over again, the first step is to have a part made through computer software designed specifically for visualizing 3D parts. This model will be translated to code that instructs a CNC machine when it is running. The choice of fitting tool is crucial when it comes to the cutting process - with end mills and drills. With a 5-axis system, the machine moves in multiple dimensions around and cuts out your titanium part. This is taking the final part to near perfect quality and allows movements like cutter displacement that otherwise need a complex jig are now able to be done autonomously by our CNC machine.

So, to sum it up - CNC milling in titanium manufacturing emerged as a game-changer. With CNC milling, you are able to create the most amazing elements even faster and with greater precision; hence its metal makes it an ideal choice for creative or innovative purposes.

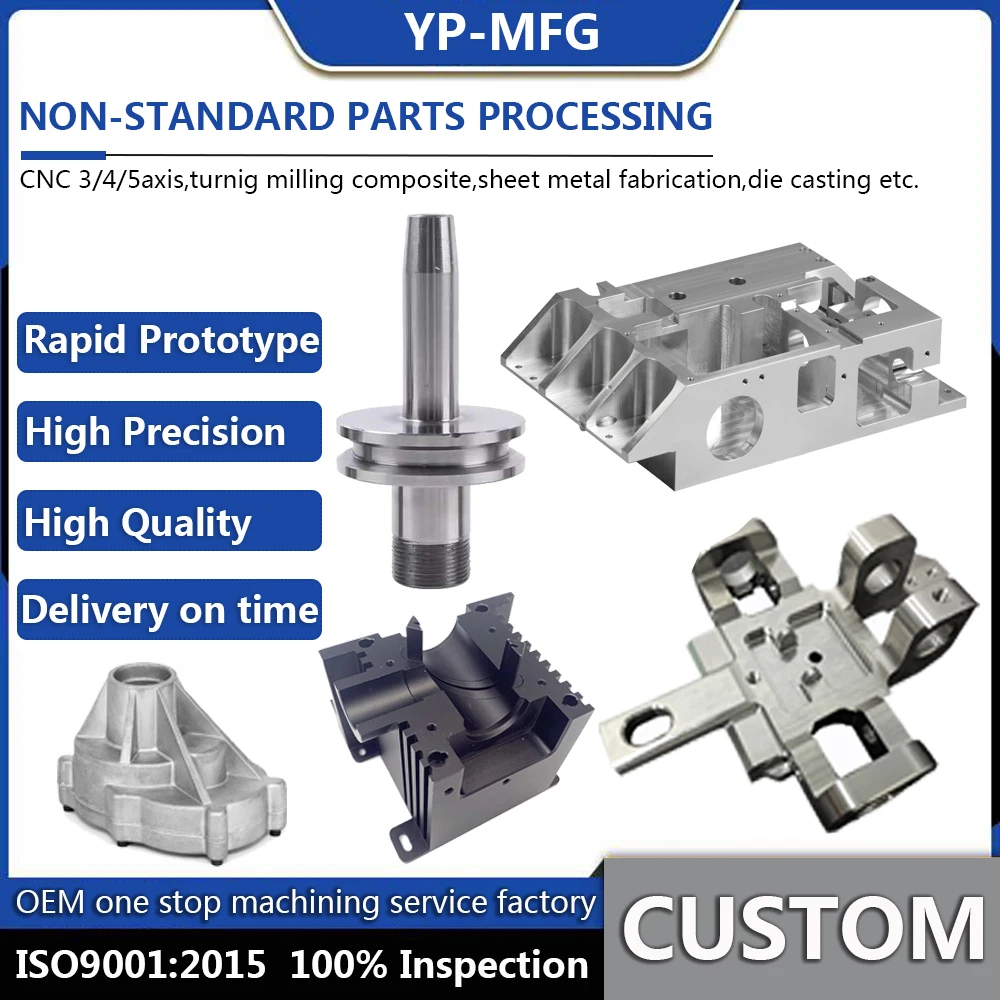

More than 70 modern machines cnc milling titanium quality speed of delivery time.have equipment made by Milron Switzerland. Brother from Japan, Jingdiao China and many more.have 15 sets 5 Axis machines, 39 sets 4 axis machines 3 axis machines, as well as 16 sets turning machines.

The YP-MFG adheres strictly to ISO 9001-2015 cnc milling titanium standards.The dimensions are tested both prior to and following surface treatment.We can satisfy special drawings needs and more.

YPMFG can offer services for CNC machine.service cnc milling titanium CNC machining, CNC turning, stamping, laser cutting, bending, die-casting, forging, all surface treatment, assembly and so on.

YP MFG is involved in cnc milling titanium machining over 20 years, our engineers are highly skilled.Our customer are from allover the world, EU, US, AU, Asian.More than 90 percent of our products exported to countries around the world.With our experience of 20 years, we are able to recognize different cultural and demand from different places and the various requests that used in various places.