CNC production services are something new and efficient way that is used in many factories for fast and precise product. They rely on Computer numerical control (CNC), a process that automates the operation of machine tools in order to produce items with great precision. This reduces the production time and cost for these companies as well.

The most critical benefits of employing CNC production services are the customization features suitable for unique demands across all industries. By instructing the computer to produce items in just that way and no other-the engineers' fantasy of having it exactly their own (specific) way guaranteed-businesses can untangle themselves from inventory constraints by getting out customized products quickly, correctly. Eliminating Hand-made Characteristics: The machines are also able to reproduce the same item several times in precise way, ensuring that all levels of quality and uniformity can be maintained.

What is CNC production? CNC means Computer Numerical Control i.e. controlling the manufacturing process in a factory using computers as opposed to manual labor or use of manpower mechanisms running on engines like that used by many orbits.

Why CNC Production Services Work for You The characteristics of these services are time and cost-saving, configurable to needs, continuously evolving with technological advances at a global level.

How do CNC machines work? The machine can be programmed by a computer program in order to take raw materials and form them into the final product.

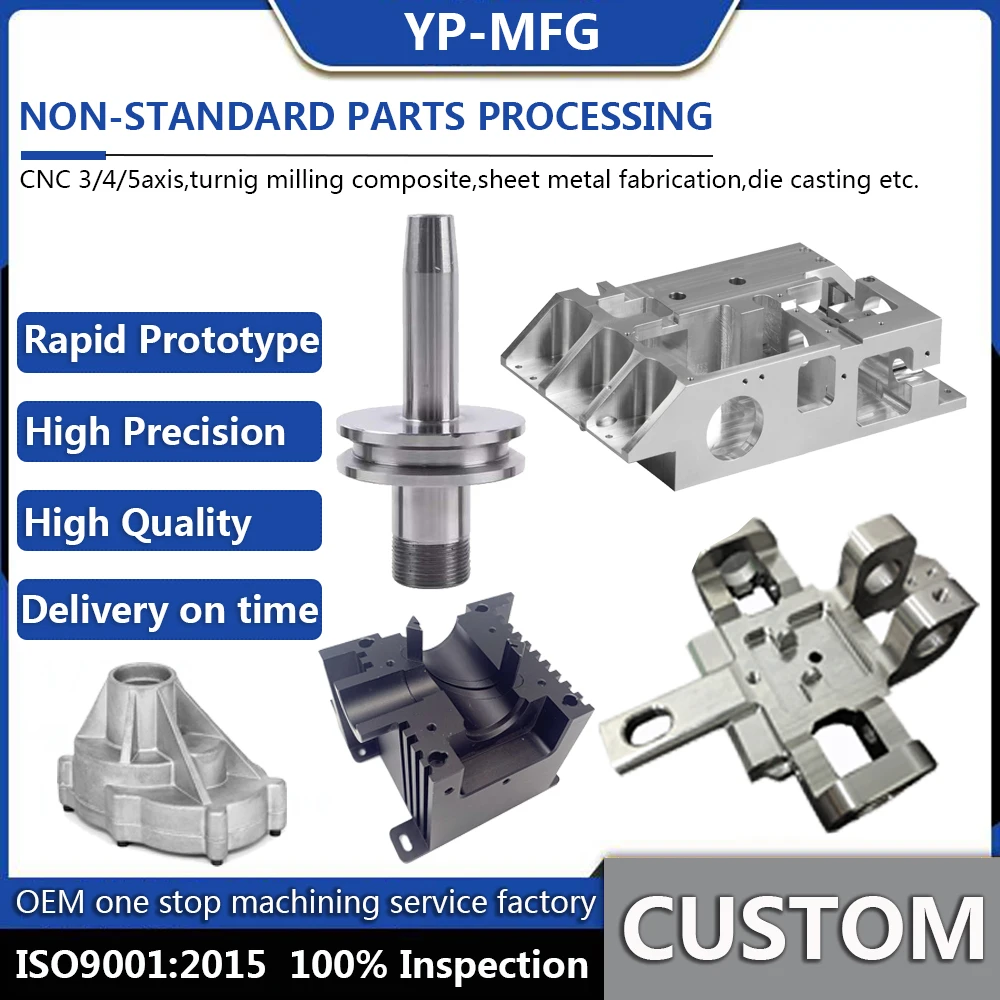

The company strictly adheres to ISO 9001-2015 cnc production service processing.The quality checked from material that arrives at our factory, the initial piece of material is checked using CMM. It's also dimension checked before surface treatment and after treatment, and surface quality checked prior to packing.Tolerence standards are generally our standard is ISO 2768-F, We can also satisfy with drawings that meet specific requirements.

YP MFG has been in cnc production service manufacturing for since the year 2000, our engineers are highly experienced.Our customer are from allover the world, EU, US, AU, Asian.More than 90 percent of our products exported all over the world.During this 20 years experience, we know different culture and request of different areas and requests that used in different areas.

YPMFG offer a variety for CNC cnc production service.service include CNC, milling, CNC turning, stamping, laser cutting, bending, die-casting, forging, all kind treatment, assembly so on.

More than 70 latest machines assure highest quality timely delivery time.equipment includes Milron from Swiss, Brother from Japan, Jingdiao from China more.have 15 sets 5 Axis machines, 39 sets of 4 Axis cnc production service 3 axis machines. There also 16 sets turning machines.