What CNC Stainless Steel Machining Is All About CNC Stainless Steel Machining relies on computer programs to cut parts in stainless steel, which is strong and shines beautifully. The perfect metal with which to fabricate tools, kitchen utensils, and other equipment. What is essential about it is that the parts that are made can be placed correctly and can be interacted with, which is where CNC stainless steel machining stands out. Crafting Parts to Perfection CNC stainless steel machining makes computer programs and computer machines which are programmed to cut stainless steel possible. These devices will execute the plans put into the computer program and cut exact parts according to the plans within the steel. The CNC stainless-steel machining is thus a quick and cost-effective procedure of developing components which are as near to the blueprint as possible. A multitude of Parts that can be fabricated Since CNC machining is so adaptable, a variety of stainless steel parts can be manufactured – including components including gears and bolts and screws and much more. If well-constructed, the cabin can even be made in such a manner with more parts that will not be able as well as other methods to fabricate. Hence, they open the prospects of producing the kinds of extremely difficult ones because of their capability to make a fine line meaningful. Seeking Proficient Assistance People can merely get optimal outcomes in stainless steel parts service consumers seek assistance from expert machinists. This team is skilled in how to operate the devices safely and consistently to guarantee that the parts are designed with precision. Moreover, they know everything stainless steel type to select the appropriate ones ages of tremendous characteristics’ and strengths can be found in numerous models. Leveraging Innovative Technologies The improvement of CNC machines has enabled the designing of special features and has aided in producing high-quality stainless steel parts. With the aid of unique hardware and software, programs are uploaded into the device, and they all go ahead to cut certain components in that steel with a thickness not yet achieved. The improvement of CNC software has improved the strength of parts. Serving the Growing Manufacturing Market Demand for stainless steel parts is still strong and spirited and is predicted to rise, in part because of the aerospace, automotive, and medical engineering industries – CNC machining serves this escalating demand by producing parts faster and more affordable. This is accurate because it is a must for the manufacturing method parts —the more certifications get items rendered-quality signs certain aspects of the life of the producing entity.

Thanks to the flexibility of CNC machining, it is possible to create a whole host of stainless steel components - anything from gears and bolts through screws up all away across applications like medical implants. Furthermore, such a method can create complex shapes and designs that are otherwise impossible to produce using other manufacturing processes. This has opened up the possibility to create elaborate shapes that are impossible with other methods due to their capacity for incredibly fine grained movement.

To provide people with accurate results in the stainless steel parts service, professionals need expert machinists. This team of professionals know how to operate these machines correctly and ensure that parts are made with precision. Furthermore, they are experts at working out the most suitable type of stainless steel for every job which includes wonderful properties and strengths present in various versions.

The advancement in CNC technology has resulted in new features that have enabled the production of high quality stainless steel parts. With the aid of unique hardware and software, these machines are programmed to cut specific pieces from the steel with unparalleled precision. This advancement in technology ensures the components made are tough and durable.

Fulfilling the Expanding Manufacturing Market

Stainless steel parts are in high demand and it is still growing, especially with aerospace, medical, automotive industries. CNC machining fulfills this growing need by producing parts faster and in the most cost-effective manner. The accuracy of this approach guarantees the production items conform to quality standards, which is indicative of their life span and credibility. At the end of the day, CNC machining is still a critically important method for building necessary stainless-steel components used by all sorts of products and industries.

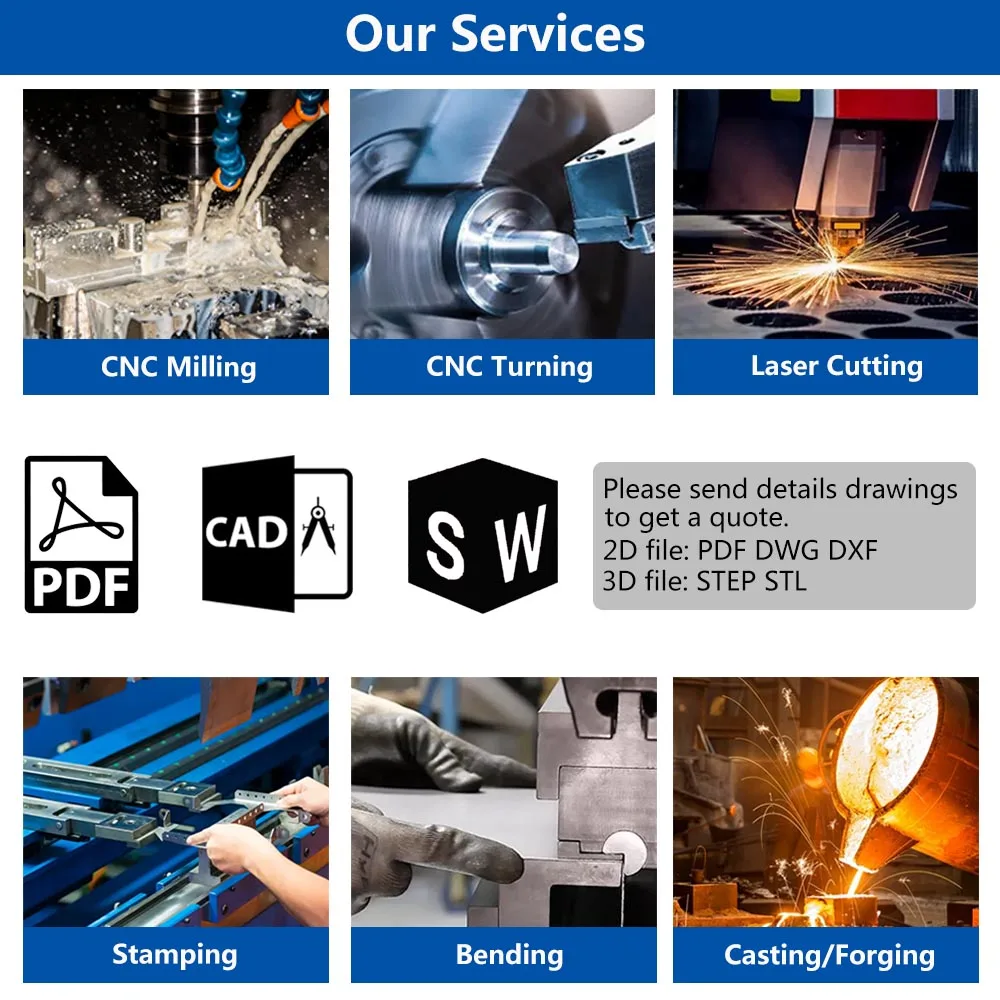

YP MFG offers an array of CNC machining services.service include CNC machining, CNC, CNC turning, stamping, laser, cnc stainless steel machining, die-casting, forging, all kind surface treatment, assembly and so on.

YP MFG has been in cnc stainless steel machining machining over 20 years, our engineers are extremely experienced.Our customer are from allover the world, EU, US, AU, Asian.Exports of more than 90 percent of our product to the rest world.Through our 20 years of experience, we understand different request and culture from different regions and the different requirements that are utilized in various places.

YP MFG is a strict adherent to ISO 9001:2015 for cnc stainless steel machining processing.All dimensions are checked before and after surface treatment.We can satisfy special drawings demands as well.

YP MFG equipped with more 70 latest machines cnc stainless steel machining quality and timely speed delivery.We have equipment that come from Milron Switzerland. Brother from Japan, Jingdiao, China, and more.We have 15 sets 5 axis machines, 39 sets 4 Axis machines 3 axis machines. also have 16 sets turning machines.