What is custom CNC machining, and what does it entail? Powered by sophisticated software, these machines can function on auto-pilot and deliver detailed parts. The process is popular because of its accuracy and speed, particularly for complex components.

Custom CNC machining services generate parts of the highest caliber to precise client specifications. Among the relevant industries for custom CNC machining, this process can be applied to a large variety of materials; from metals and plastic are obviously used in many ways up to composites. Such a high level of precision makes CNC machining great for companies who want to make prototypes and test parts before starting mass production, allowing the company more time as well as resources spent on product development.

Getting a reliable custom CNC machining outsource service is like winning the lottery for any business wishing to please its clients with best of class parts. Automated and high through-put nature of IHC procedure saves labor cost, improves productivity since Automation reduces manual labour requirement hence providing better reproducibility and accuracy in final product. Moreover, because CNC machines are also capable of producing a high volume of parts in quick fashion, properties will never miss their deadlines as they deliver top quality custom components. Custom CNC machining services allow businesses to handle large orders and decrease costs of production, two factors which will invariably translate into a healthier bottom line.

Custom CNC Machining is one of the leading services that are altering the manufacturing industry for good. More accurate & precise than traditional manufacturing methods, this disruptive process is well-suited for creating the complex geometries found in modern products. Above all, CNC machines are known for their versatility as they can produce a variety of parts and shapes with precision and speed that conventional equipment cannot match. As a result, it is saved from production tooling and retool changeovers which means that Maltese moulds can be easily inserted in flexible way this saves time as well as resource.

To end this, CNC machining service is an essential part of the modern manufacturing landscape. These properties of the molds have led many businesses to use them for manufacturing regular and accurate component parts. As technological evolutions like the cost of CNC machining going lower day by day it is making things customizable keeping other costs to a bare minimum hence its application ranges are increasing across multiple industries. By embracing custom CNC machining services, a company will be able to provide the modern solutions that are needed for the market and this makes it more competitive up against other businesses in its specific field as well.

YP MFG has been in custom cnc machining services machining over 20 years, our engineers are extremely experienced.Our customer are from allover the world, EU, US, AU, Asian.Exports of more than 90 percent of our product to the rest world.Through our 20 years of experience, we understand different request and culture from different regions and the different requirements that are utilized in various places.

YP MFG has more than 70 modern machines ensure quality time delivery.have custom cnc machining services from Milron Switzerland, Brother from Japan, Jingdiao China many more.There 15 sets of 5 axis machines, 39 sets 4 axis machines and 3 axis machines as well as 16 sets turning machines.

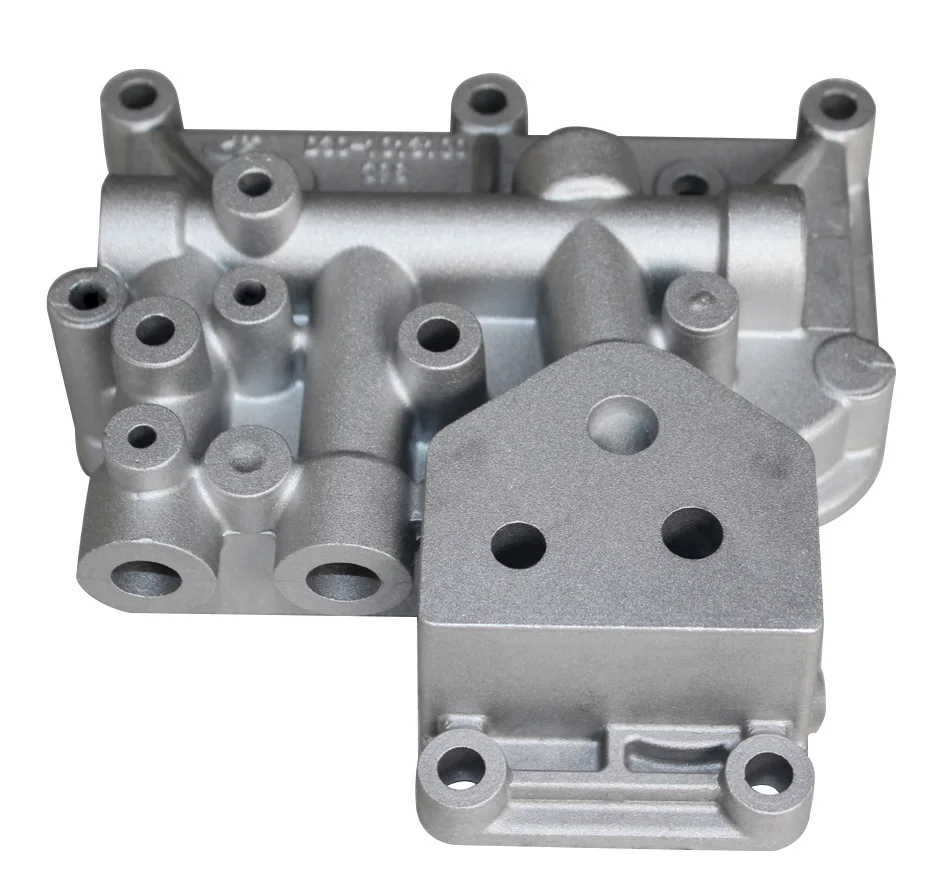

YP MFG offers an array of CNC machining services.service include CNC machining, CNC, CNC turning, stamping, laser, custom cnc machining services, die-casting, forging, all kind surface treatment, assembly and so on.

The company strictly adheres to ISO 9001-2015 custom cnc machining services process.The quality was checked before material arriving to our factory, the first piece is inspected by CMM, and all dimensions checked prior to surface treatment and afterwards, and then the surface inspection prior to packaging.We can also meet any special drawing requirements and more.