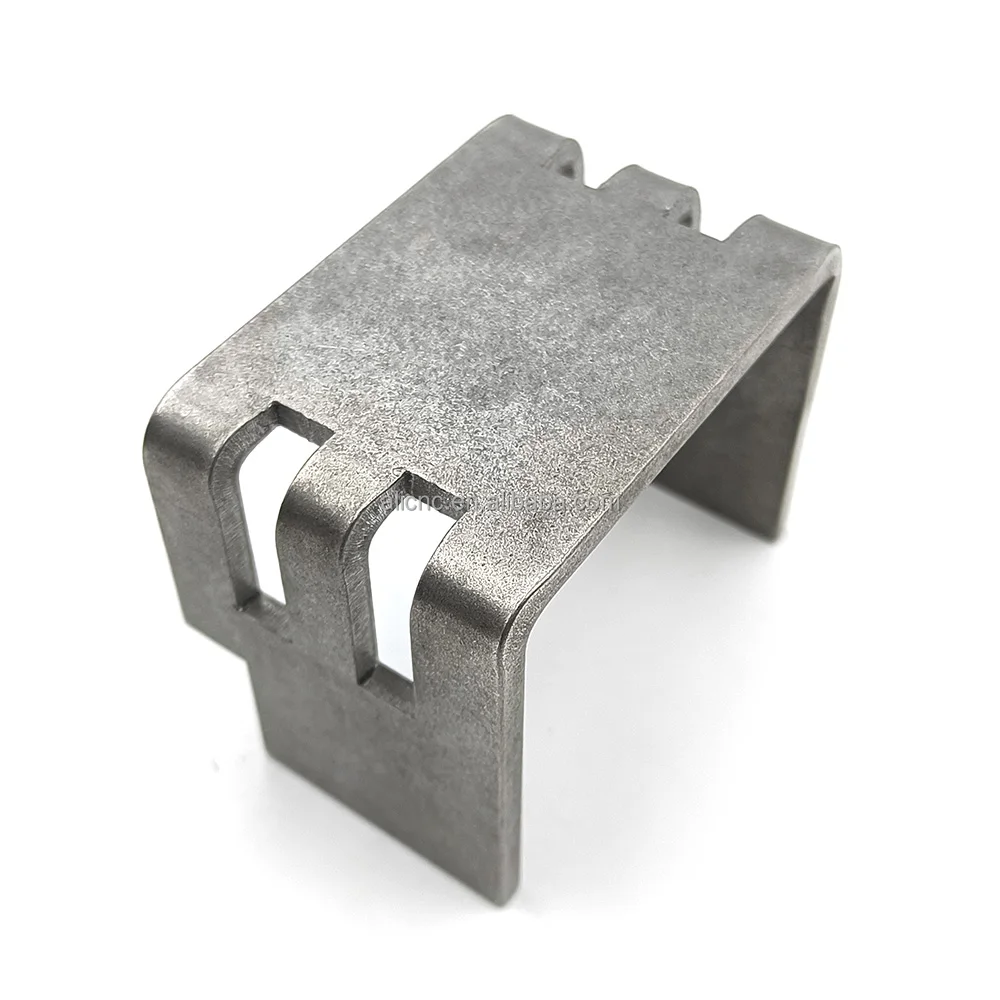

Stunning Uses of Custom Sheet Metal Stamping 1. This is a particular method, use machines in cutting and shaping metal into your required size and form. It has high repeat accuracy so that stainless steel debris, always complies exactly. This accuracy is imperative because it guarantees that each part will be a perfect fit within the project for which they are necessary.

We think that custom sheet metal stamping is great for just about any kind of project. For instance, when building a car, metal pieces are required to hold everything together and ensure it runs smoothly. And for if you're building a machine, specific parts to ensure everything stays still and in the right place It matters little what you are producing - a mini widget, or something massive like machinery custom sheet metal stamping ensures that those parts manufactured to meet your specifications in fine details.

If you opt for it, then you are assured of the fact that the components will be robust and in good condition. This results in very precise and well-fitted parts that will resist breaking for a long time. Since you might be manufacturing machines or anything else for that matter which have to reliable and safe, durability is also very important. And you will also have the peace of mind (and your pocketbook) knowing that these parts are not going to wear out on a regular basis.

In addition, there is also custom sheet metal stamping in which you can carve out designs and shapes of your choice. The machinery employed in this method are able to replicate any type of design and contours, essentially allowing you to be as creative with your concepts. Great if something important you are creating should make an impression, such as a special product (e.g. customers) or even art You can learn different formats to flicker the eyes of people, and it will stand out from other projects.

Last but not least, handmade sheet metal stamping keeps your business solvent from the metallic parts manufactured in a cheap way. With a quick and efficient manufacturing process, many parts can be produced at an economical price. And that efficiency matters when you're trying to build cost savings without sacrificing great components. It makes it easier for business to compete by keeping costs down and freeing up budget in other areas.

The YPMFG brand has been involved in custom sheet metal stamping manufacturing for more than 20 years. Our engineers are skilled.Our customer are from allover the world, EU, US, AU, Asian.More than 90% of our products are exported to countries around the world.We have over 20 years of experience, and we have a deep understanding of the different styles and needs of various regions.

YP MFG boasts more than 70 latest machines ensure the highest quality custom sheet metal stamping the speed of delivery.have machines come from Milron Switzerland. Brother from Japan, Jingdiao China and more.There are 15 sets of 5 Axis machines, 39 sets 4 axis machines 3 axis machines as well as 16 sets of turning machines.

YP-MFG custom sheet metal stamping range services for CNC machining.Us include CNC machining, CNC milling, CNC turning, stamping, laser cutting, bending, die-casting, forging, all kind of surface treatment, assembly and so on.

YP-MFG strictly adheres to ISO 9001-2015 custom sheet metal stamping standards.The quality of the material is checked upon that arrives at our factory, the initial piece is inspected by CMM, and all dimension checked before surface treatment and after treatment, and surface quality checked prior to packing.We are able to meet special drawing needs as well.