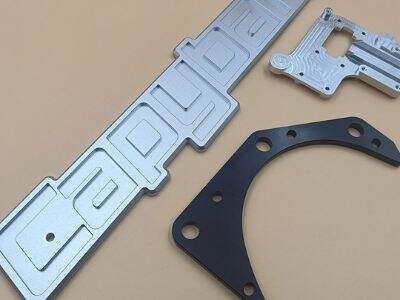

Heute werden wir über leichte Teile sprechen, die aus den beiden speziellen Metallen hergestellt werden: Aluminium und Titan. Diese Metalle können für Flügel von Flugzeugen, Fahrradrahmen, Raketenkomponenten und vieles mehr verwendet werden. Sie sind außerdem extrem stark und dabei extrem leicht. Dies ist entscheidend, wenn man Stabilität ohne das Gewicht ermöglichen möchte.

Aluminium und Titan erklärt

Aluminium ist ein weiches, leichtes Metall, das einfach zu verarbeiten ist. Es ist auch weniger teuer als Titan, was es für viele Anwendungen interessant macht. Das gesagt, ist Aluminium nicht ganz so stark wie Titan, daher könnte es nicht die ideale Lösung für Komponenten sein, die erhebliche Belastungen oder Dehnungen aushalten müssen.

Titan ist ein extrem starkes und leichtes Metall. Es wird hauptsächlich in Anwendungen eingesetzt, wo Gewicht wichtiger als Kosten ist, wie in der Luft- und Raumfahrtindustrie. Da jedoch Titan teurer ist als Aluminium, eignet es sich nicht für jedes Projekt.

Aluminium und Titan: Leistung und Kosten

Titan ist leistungsfähiger und haltbarer als Aluminium, wenn es um die Leistung geht. Das ermöglicht ihm, größeren Verschleiß und Missbrauch zu ertragen. Diese verbesserte Leistung geht jedoch mit einem höheren Preis für Titan einher.

Aluminium ist nicht so stark, aber es ist ein gutes Material für viele Aufgaben. Es ist günstiger und einfacher zu verarbeiten, was eine bessere Option für Pläne mit begrenztem Budget sein kann.

Aluminium und Titan: Hohe Stärke-Gewicht-Relation

Das Verhältnis von Stärke zu Gewicht eines Materials zeigt uns, wie stark das Material im Vergleich zu seinem Gewicht ist. Aluminium und Titan haben gute Stärke-Gewicht-Verhältnisse, aber Titan hat hier den Vorteil. Das bedeutet, dass Titan potenziell stärker und leichter als Aluminium sein kann, was ihn großartig für Anwendungen macht, in denen das Gewicht eine Rolle spielt.

Rostfest und korrosionsbeständig

Titan triumphiert erneut, wenn es um Haltbarkeit geht. Er ist rostbeständiger als Aluminium und kann unter schwierigen Bedingungen länger halten. Deshalb findet man Titan oft in rostempfindlichen Umgebungen, wie zum Beispiel in der Seefahrt.

Aluminium dagegen ist eher anfällig für Korrosion und könnte in einigen Umgebungen nicht so lange halten. Natürlich kann Aluminium, wenn es richtig gepflegt wird, immer noch eine ausgezeichnete Wahl für viele Projekte sein.

Aluminium oder Titan?

Letztendlich hängt die Entscheidung zwischen Aluminium und Titan von den spezifischen Anforderungen Ihres Projekts ab. Wenn Stärke und Haltbarkeit übergeordnete Aspekte sind, könnte Titan die bevorzugte Option sein, auch wenn er teurer ist. Wenn Kosten und Bequemlichkeit ebenfalls wichtige Faktoren sind, dann könnte Aluminium die richtige Wahl sein.

Bei Leichtbau individuelle Metallfräser , ist die Auswahl des richtigen Materials entscheidend. Wir können Ihnen helfen, die richtige Lösung für das Projekt zu finden, sei es, dass Sie die Widerstandsfähigkeit von Titan benötigen oder die wirtschaftlichen Möglichkeiten von Aluminium. Um mehr über unsere Dienstleistungen und wie wir Ihnen bei Ihrem nächsten Leichtbau-Projekt helfen können, kontaktieren Sie uns heute.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS